Cell Types & Chemistry

Cell Types & Chemistry

Introduction to LTO (Lithium Titanate) Batteries

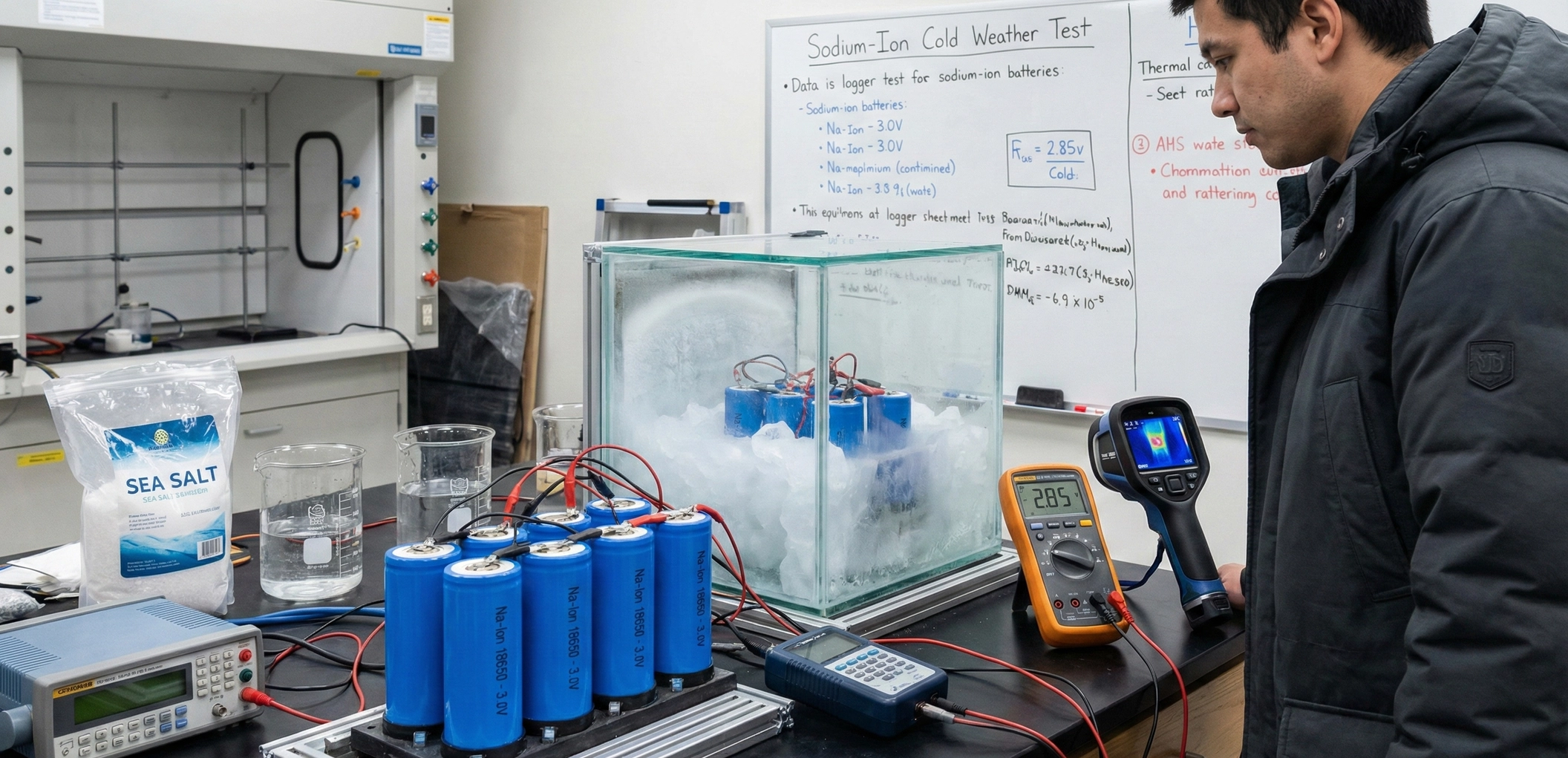

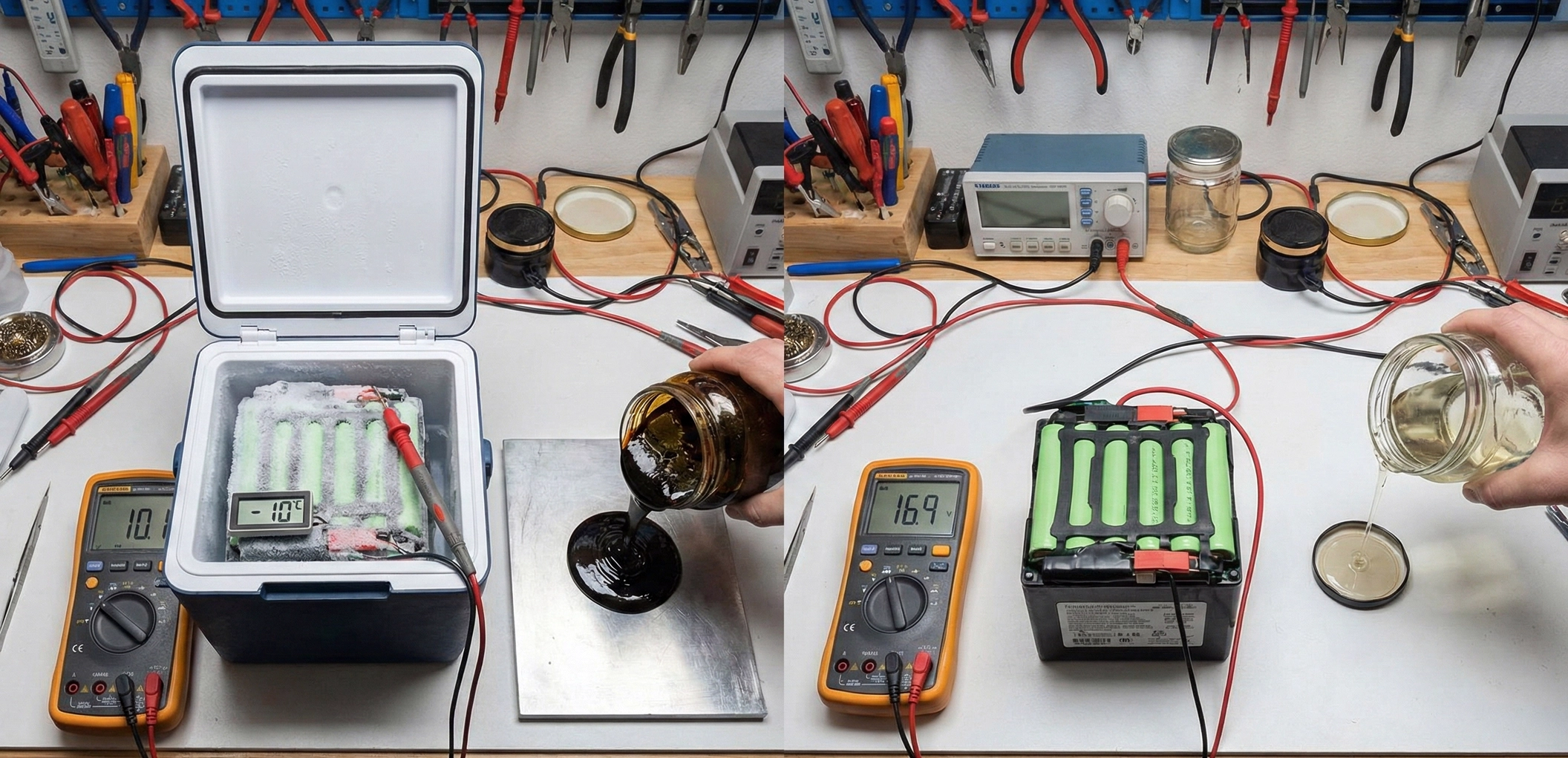

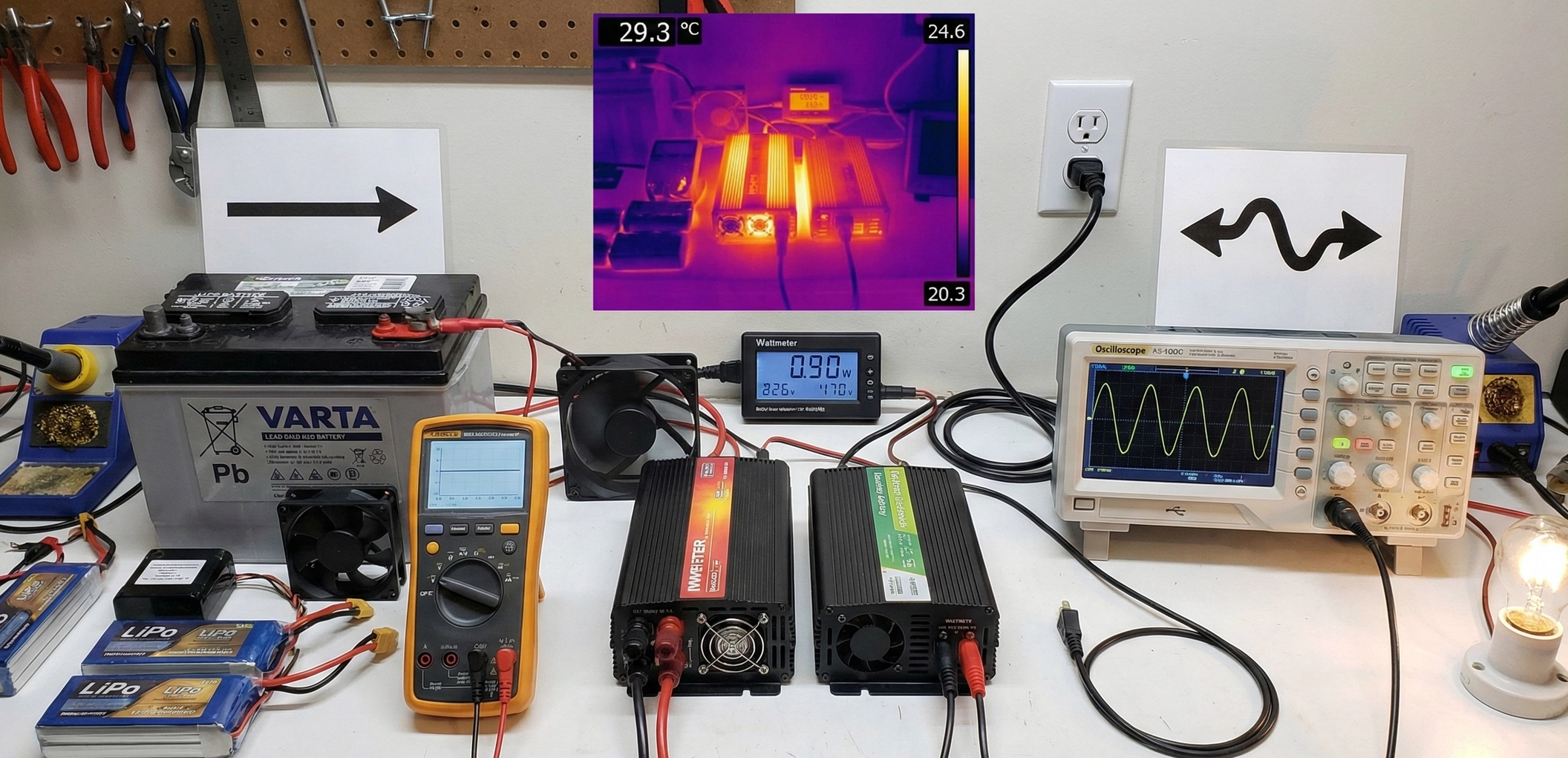

The Battery That Outlives the ApplicationIn the world of lithium batteries, there is always a trade-off. If you want high energy density, you sacrifice safety (NMC). If you want safety and long life, you accept heavy weight (LFP). But sitting in a corner, largely ignored by the mainstream, is a chemistry that breaks almost all the rules of degradation: Lithium Titanate Oxide (LTO).LTO is not just an incremental improvement; it is a fundamental redesign of the anode. While standard lithium-ion cells use Graphite to hold lithium ions, LTO uses nanocrystals of Lithium Titanate. This change grants the battery superpowers: 20,000 to 30,000 cycles, extreme safety, and massive power delivery. It is the closest thing we have to a "forever battery."1. The "Zero Strain" PropertyWhy do batteries die? In Graphite anodes (used in NMC and LFP), the intercalation (insertion) of lithium ions causes the graphite lattice to expand by about 10%. Over thousands of cycles, this constant breathing causes the material to crack and degrade. The Internal Resistance rises, and the cell fails.LTO crystals, however, have a "Zero Strain" property. When lithium ions enter the titanate structure, the volume change is negligible (less than 0.2%). There is no mechanical stress. Because the structure doesn't physically break down, the cycle life is astronomical.NMC: ~800 Cycles.LiFePO4: ~4,000 Cycles.LTO: ~25,000+ Cycles.If you cycle an LTO battery once a day, it would theoretically last 68 years. The battery will likely outlive you.2. Extreme Temperature PerformanceWe typically warn builders never to charge lithium below freezing. Doing so causes lithium plating, which destroys the cell. (See our Temperature Guide).LTO is the exception. The electrochemical potential of the Titanate anode is higher (1.5V vs Li) than Graphite (0.1V vs Li). This means lithium plating is thermodynamically impossible under normal conditions, even at extreme discharge rates or low temperatures.Operating Range: You can safely charge and discharge LTO cells at -30°C (-22°F). For Arctic expeditions, aerospace applications, or unheated cabins in Canada, LTO is often the only chemistry that works without complex heating systems.3. The Power of C-RatingsBecause the nanocrystals have a massive surface area (100 m²/g vs 3 m²/g for graphite), ions can move in and out with incredible speed.Charge Rate: 6C to 10C. (0% to 100% in 6-10 minutes).Discharge Rate: 10C to 30C continuous.This behavior makes LTO act almost like a Supercapacitor. It is widely used in electric buses that charge for 5 minutes at every bus stop, and in high-end Car Audio competitions where thousands of amps are needed instantly to prevent voltage drop on bass hits.4. The Downsides (Why it isn't everywhere)If LTO is so perfect, why doesn't Tesla use it?A. Energy Density (The Weight Problem)LTO has a very low cell voltage (2.3V or 2.4V nominal) and the materials are heavy. Gravimetric Density: ~80 Wh/kg. This is half the density of LFP and one-third of NMC. An LTO battery pack for a Tesla Model S would weigh 3,000 lbs. It is simply too heavy for long-range EVs or portable electronics.B. Low Voltage = More CellsBuilding a 12V or 48V battery requires more cells in series.12V Nominal: LFP needs 4 cells (4S). LTO needs 5 or 6 cells (5S is 12.0V, 6S is 14.4V).48V Nominal: LFP needs 16 cells (16S). LTO needs 20 to 22 cells (22S).More cells mean more connections, more complexity, and larger BMS wiring harnesses.C. CostTitanium is more expensive than Carbon. Manufacturing volumes are lower. LTO currently costs roughly $400-$600 per kWh, compared to $100-$150 for LFP. The upfront cost is massive, even if the "Total Cost of Ownership" over 30 years is lower.5. BMS ChallengesYou cannot use a standard Li-Ion or LiFePO4 BMS for LTO. The voltage range is completely different.Max Voltage: 2.8V - 2.9VNominal Voltage: 2.3V - 2.4VMin Voltage: 1.5V (can go to 0V safely, but BMSs cut higher).If you connect a standard BMS, it will think the cell is "dead" (Under Voltage Protection) at 2.4V. You must buy a specialized LTO Smart BMS or a fully programmable unit where you can manually set the thresholds.6. Form Factors: The Yinlong CylindersThe most common LTO cells available to DIYers are the cylindrical Yinlong 66160 cells (66mm diameter, 160mm length). Specs: 40Ah capacity. These huge blue cylinders feature threaded studs, making them easy to assemble with busbars. However, due to the high current capability (10C = 400 Amps!), you must use massive copper busbars and ensure torque specs are perfect to avoid melting the terminals.Conclusion: Who is LTO for?LTO is a niche, high-performance chemistry. It is not for the average solar homeowner (buy LFP for that). Build with LTO if: 1. You live in extreme cold and need charging without heating. 2. You need a battery that will last 30 years without maintenance (remote telecom towers). 3. You need extreme power density (Car Audio, Drag Racing). 4. You want the absolute safest lithium chemistry known to man (highly resistant to thermal runaway even when punctured).