Solar Systems

Solar Systems

Top Balancing Large Prismatic LiFePO4 Banks

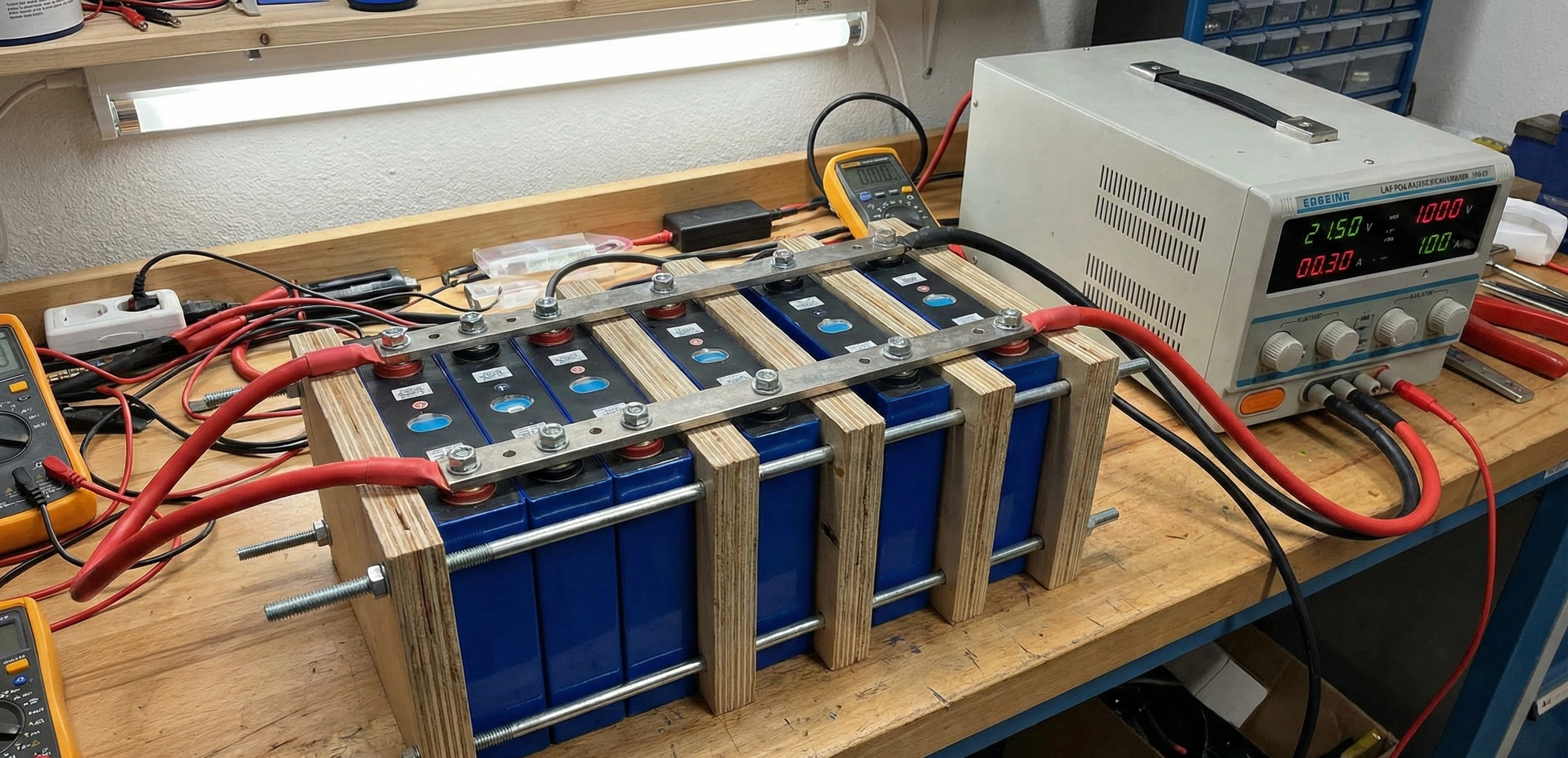

The Myth of the Factory Balanced CellYou have just received a heavy wooden crate containing sixteen 280Ah LiFePO4 prismatic cells. You measure them with a high-precision multimeter, and they all read exactly 3.29V. You might think, "Perfect, they are identical, I can build my 48V pack now." If you do this, you are making a fundamental error that will limit your battery capacity and frustrate you for months to come.Voltage, especially in the middle of the Lithium Iron Phosphate discharge curve, is an incredibly poor indicator of State of Charge (SOC). Because LFP has a famously flat voltage profile, two cells at 3.29V could actually be 20% apart in their actual energy content. One could be at 40% SOC, and the other at 60%. When you connect them in series, this minor discrepancy becomes a massive operational wall. This guide explores the chemistry and the rigorous procedure of Top Balancing—the non-negotiable process of synchronizing cells at their upper saturation point before assembly.1. Why Series Balancing is Not EnoughMost beginners believe that a BMS with balancing will eventually fix the pack. This is mathematically impossible for large banks. A standard passive BMS bleeds off energy at 30mA to 50mA. In a 280Ah pack, a 10% SOC difference is 28 Amp-hours. The Math: $28Ah / 0.050A = mathbf{560 hours}$ of continuous balancing. The BMS only balances when the battery is at the very top of the charge (the "Knee"). Since your charger only stays at that voltage for 30-60 minutes a day, it would take over a year of daily cycles for the BMS to fix a 10% drift. During that year, the high cell will constantly trip the Over-Voltage Protection, cutting off the charger and leaving the rest of your pack undercharged. You effectively "lose" a huge chunk of the battery you paid for.2. The "Knee" of the LFP CurveTo understand top balancing, you must understand the LFP voltage curve. From 20% to 80% SOC, the voltage stays around 3.2V to 3.3V. However, as the cell reaches 95% SOC, the voltage "hits the knee" and shoots up rapidly toward 3.65V. Top balancing ensures that every cell hits this knee at the exact same microsecond. If they aren't balanced, one cell will rocket to 3.65V while the others are still lagging at 3.40V. The BMS sees the "runner" cell hitting the safety limit and shuts down the charge, even though the total pack energy is far from full.3. The Parallel Saturation Method: Step-by-StepThis is the industry-standard method for DIY builders. It involves turning all your cells into one giant 3.2V cell so they have no choice but to equalize.Step 1: The Initial Series Charge (Optional but Recommended)Charging 16 large cells in parallel from 30% to 100% using a small lab power supply can take two weeks. To speed this up, assemble the pack in its final 16S (48V) configuration with a BMS. Charge the pack until the first cell hits 3.50V. Stop the charge. The pack is now roughly 95% full.Step 2: The Parallel TransitionDisassemble the series connections. Lay your cells side-by-side. Use copper busbars to connect all Positives together and all Negatives together. CRITICAL WARNING: Before connecting the last busbar, verify cell voltages. If one cell is at 3.2V and another at 3.5V, a massive current will rush between them. If the difference is >0.1V, use a resistor to bleed the high cell down before making the solid parallel connection.Step 3: The Lab Power Supply SetupYou need a high-quality, adjustable power supply (like an RD6006). 1. Set the voltage to 3.650V exactly. Use a calibrated multimeter to verify the supply's screen is accurate. 2. Set current to maximum (e.g., 10A or 20A). 3. Connect to the giant parallel block.Step 4: The Soak PhaseThe power supply will stay in "Constant Current" (CC) mode for a long time. Eventually, the voltage will hit 3.65V, and the supply will switch to "Constant Voltage" (CV). The amperage will start to drop. When are you done? You are finished when the current drops to near zero (e.g., < 0.5A for the whole block). This indicates that the chemical potential of the cells is perfectly matched to the 3.65V source. The anode is fully saturated across all cells.4. Common Traps: Surface Charge and ResistanceA common mistake is stopping when the voltage hits 3.65V. If you disconnect the charger while it is still pushing 5 Amps, the voltage will instantly "settle" or drop back to 3.4V. This is called Surface Charge. To have a true balance, you must hold the voltage until the chemical reaction is complete and no more current can be accepted.Also, beware of Busbar Resistance. If your power supply is connected to Cell #1, and you have 16 cells in a row, the resistance of the busbars might mean Cell #16 is seeing 3.60V while the supply reads 3.65V. Solution: Connect the Positive lead of the charger to one end of the block, and the Negative lead to the opposite end. This ensures an equal path length for all cells.5. After the Balance: The Rest PeriodOnce balancing is done, disconnect the power supply but leave the cells in parallel for another 24 hours. This allows any micro-variations in internal resistance to settle. After 24 hours, measure the voltages. They should be identical to the third decimal place. Now, you can safely reassemble them into your 48V series pack, knowing that your BMS will only have to deal with minor maintenance balancing rather than a 30Ah drift.SummaryTop balancing is a test of patience. It feels like "dead time" when you are excited to finish your solar build, but it is the foundation of system health. A pack that is not top-balanced will never deliver its full rated Watt-hours and will cause constant BMS nuisance trips. (See LiFePO4 vs Li-Ion for more on why this chemistry requires specific care). Do it once, do it right, and your battery bank will serve you for the next decade without drama.