DIY Projects

DIY Projects

Project: Building a Recycled 18650 Powerwall

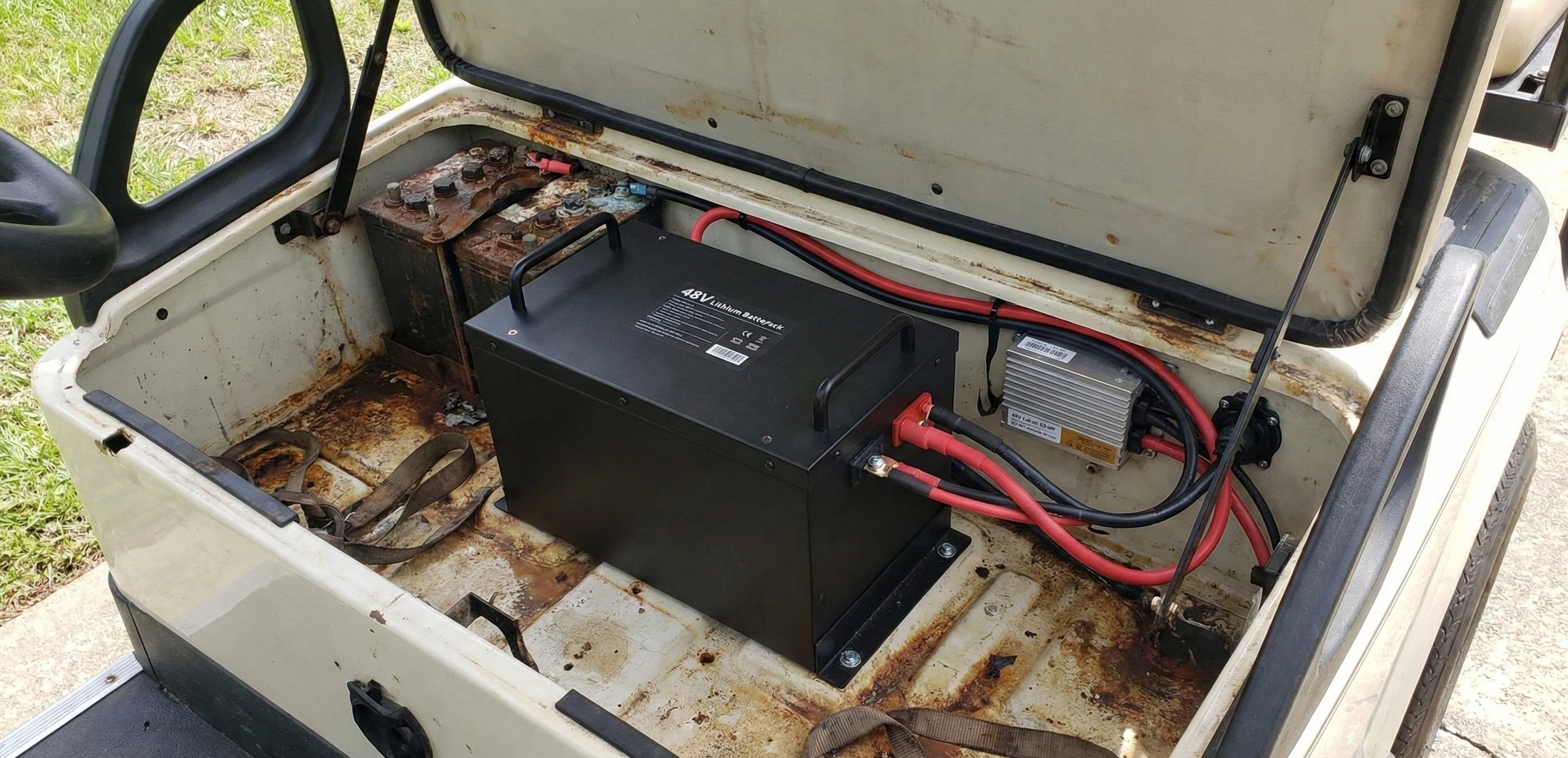

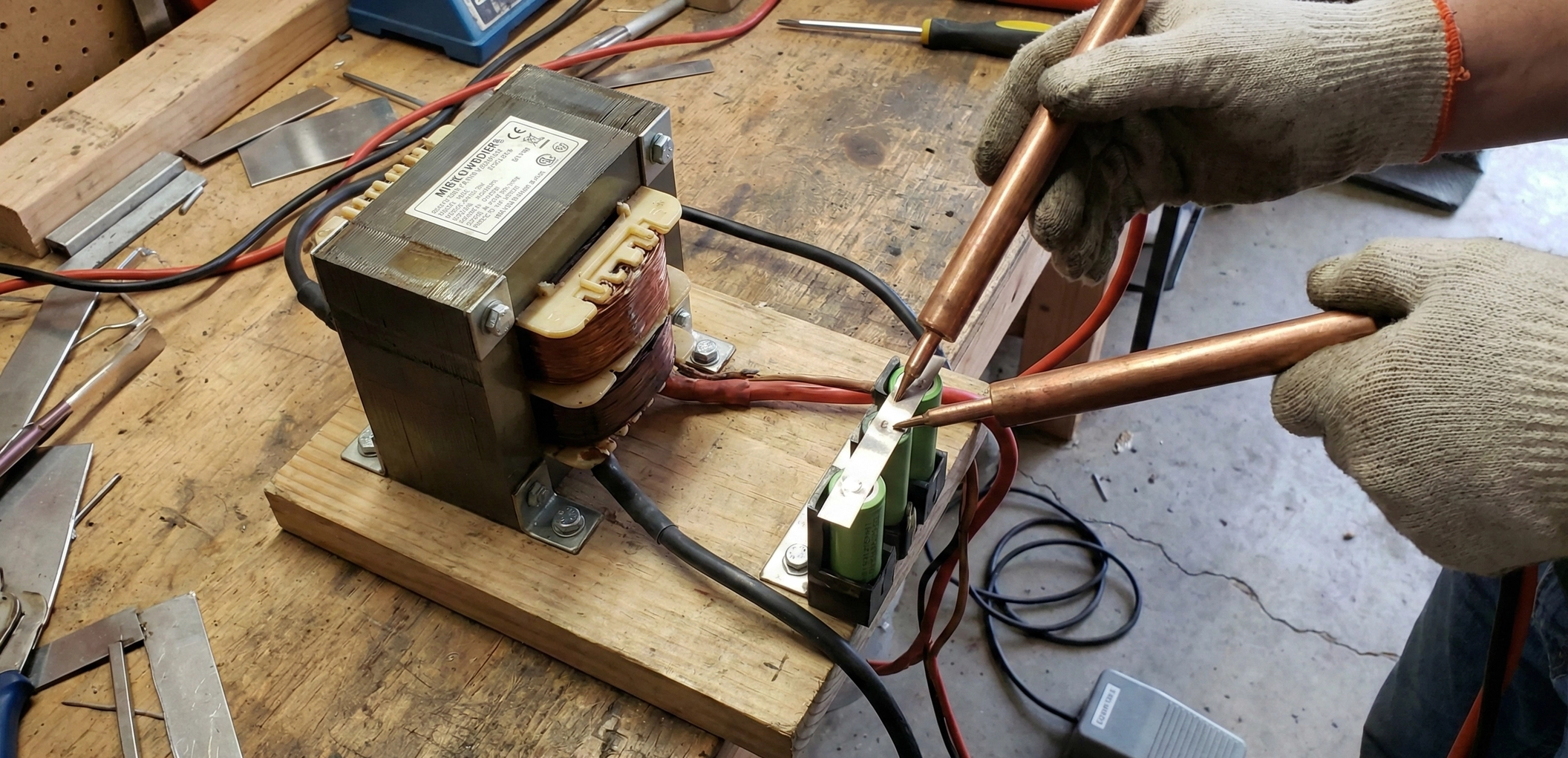

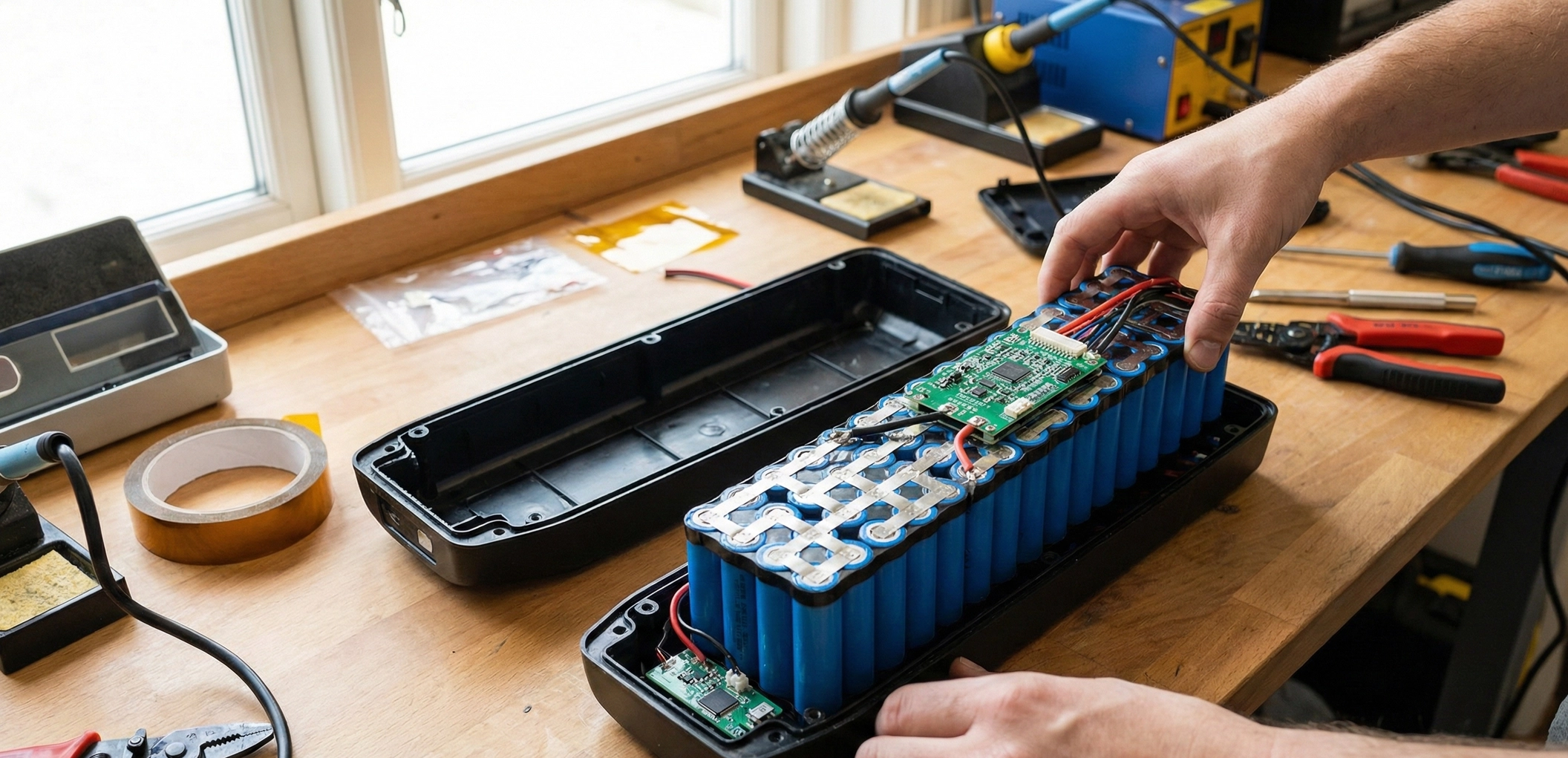

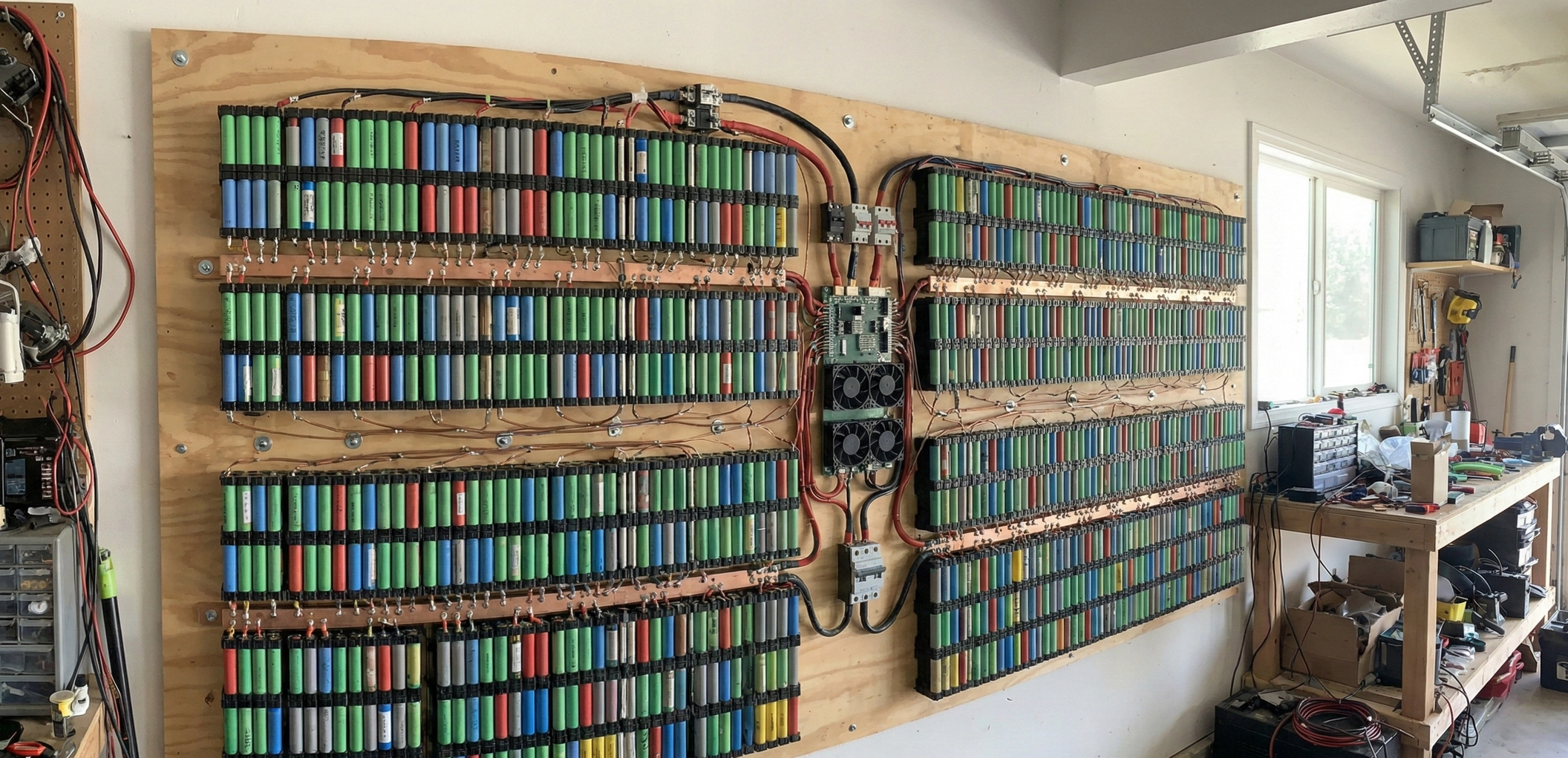

The Heritage of DIY Energy StorageBefore Lithium Iron Phosphate (LiFePO4) prismatic cells became affordable, there was only one way for an enthusiast to build a 10kWh home battery: harvesting thousands of 18650 cells from discarded laptop packs, medical devices, and modem backups. Popularized by pioneers like Jehu Garcia, this movement transformed battery building from a niche electronic hobby into a global sustainable energy revolution. Building an 18650 powerwall is not just about saving money; it is a monumental task of engineering coordination, thermal management, and fire safety design.A "Jehu Style" powerwall is characterized by its modularity. Instead of one giant, welded block, the battery is composed of dozens of smaller "packs" (typically 7S or 14S) mounted on a wall or inside a server rack. This guide explores the rigorous technical protocols required to build a massive energy reservoir from thousands of individual, aged cells without creating a hazard.1. The Logistics of the Harvest: The 1,000-Cell ChallengeTo build a 10kWh Powerwall at 48V (14S), you need roughly 1,200 to 1,400 cells, assuming an average capacity of 2000mAh per cell. However, to get 1,400 good cells, you must harvest and test at least 2,500.The Processing Pipeline:Triage: Open the laptop packs. Discard any cells with physical damage or "Leakers" (cells that smell like solvent).Voltage Check: Any cell below 2.0V is a liability. According to the chemistry of Recycled Cell Safety, these cells likely have internal copper shunts and must be recycled.Capacity Grading: Every single cell must undergo a full charge/discharge cycle. We use 4-slot or 16-slot grading stations to measure the actual mAh.The Heater Test (Self-Discharge): This is the step most beginners skip. After charging to 4.2V, cells must sit for 30 days. Any cell that drops below 4.10V is a "Heater"—a cell with internal micro-shorts that will drain your entire pack.2. The Architecture: Parallel Group BalancingIn a Powerwall, you are building a 14S80P or 14S100P monster. The most critical engineering rule is that every parallel group must have identical total capacity.If Group #1 has 200,000mAh and Group #5 has 195,000mAh, the BMS will constantly struggle. Group #5 will empty first, causing the BMS to cut off the whole wall while the other 13 groups still have 5,000mAh left. We use tools like "Repackr" to distribute cells of different capacities (e.g., mixing a 2200mAh cell with an 1800mAh cell) so that the mathematical sum of every 100-cell block is identical within 1%.3. The Safety Core: Cell-Level FusingIn a standard e-bike pack, cells are spot welded directly to nickel. In a Powerwall, this is dangerous. If one cell out of 100 in a parallel group develops a hard internal short, the other 99 cells will dump their energy into that one cell. This is 300+ Amps of current rushing through a single cylinder. Fire is inevitable.The Solution: The Fuse Wire. Instead of nickel strips, we use a busbar (often a thick copper pipe or wire) and connect each cell to it using a very thin piece of tinned copper wire (usually 30 AWG). Physics: This thin wire is designed to act as a 1A-2A fuse. If a cell shorts, the wire vaporizes instantly, isolating the bad cell from the rest of the pack. The system keeps running, and you simply replace the blown cell later. This is "Defense in Depth" at the granular level.4. Busbar Design: Managing the Main TrunkWhen you have 100 cells in parallel, the current adds up. If each cell provides 0.5A, the busbar is carrying 50 Amps. At the pack level, where multiple modules connect, you might see 200 Amps. The Copper Pipe Method: Many DIYers use 1/2" or 3/4" copper plumbing pipe as the main busbar. Copper pipe has massive surface area and zero measurable resistance for these loads. Torque and Contact: Use M8 bolts and ring terminals to link modules. A loose connection at the busbar level can reach 300°C in minutes. (See our guide on Busbar Precision for torque settings).5. BMS and Monitoring: The Digital WatchmanManaging 14 series groups of recycled cells requires a high-current Smart BMS. We typically use a 200A ANT or JK BMS. Communication: Because Powerwalls are stationary, we often integrate them with "VenusOS" or "Solar Assistant" via a Raspberry Pi. This allows you to track individual group drift from your phone. With recycled cells, you will see more "vibration" in the cell voltages compared to new LFP; a BMS with high active balancing current (1A-2A) is highly recommended to keep the old cells in line.6. Thermal Management and PlacementEnergy density is heat density. Even if your cells are only warm to the touch, 1,000 warm cells in a wooden cabinet will bake. 1. Vertical Airflow: Mount the packs with at least 1-inch of space between them. Natural convection will pull cool air from the bottom. 2. Enclosure: Never build a Powerwall in a wooden frame. Use a metal server rack or a cinder-block enclosure in a garage. 3. Temperature Probes: Place at least four NTC probes at various heights in the rack. Heat rises; the top packs will always be 5-10°C hotter than the bottom.SummaryBuilding a Jehu-style 18650 Powerwall is a labor of love that rewards the meticulous. It is the ultimate expression of the circular economy—taking "waste" and turning it into a 20-year energy asset. While LiFePO4 prismatics are easier to assemble, the 18650 wall teaches you more about the physics of Internal Resistance and current sharing than any other project. Build it modular, fuse every cell, and respect the amps.